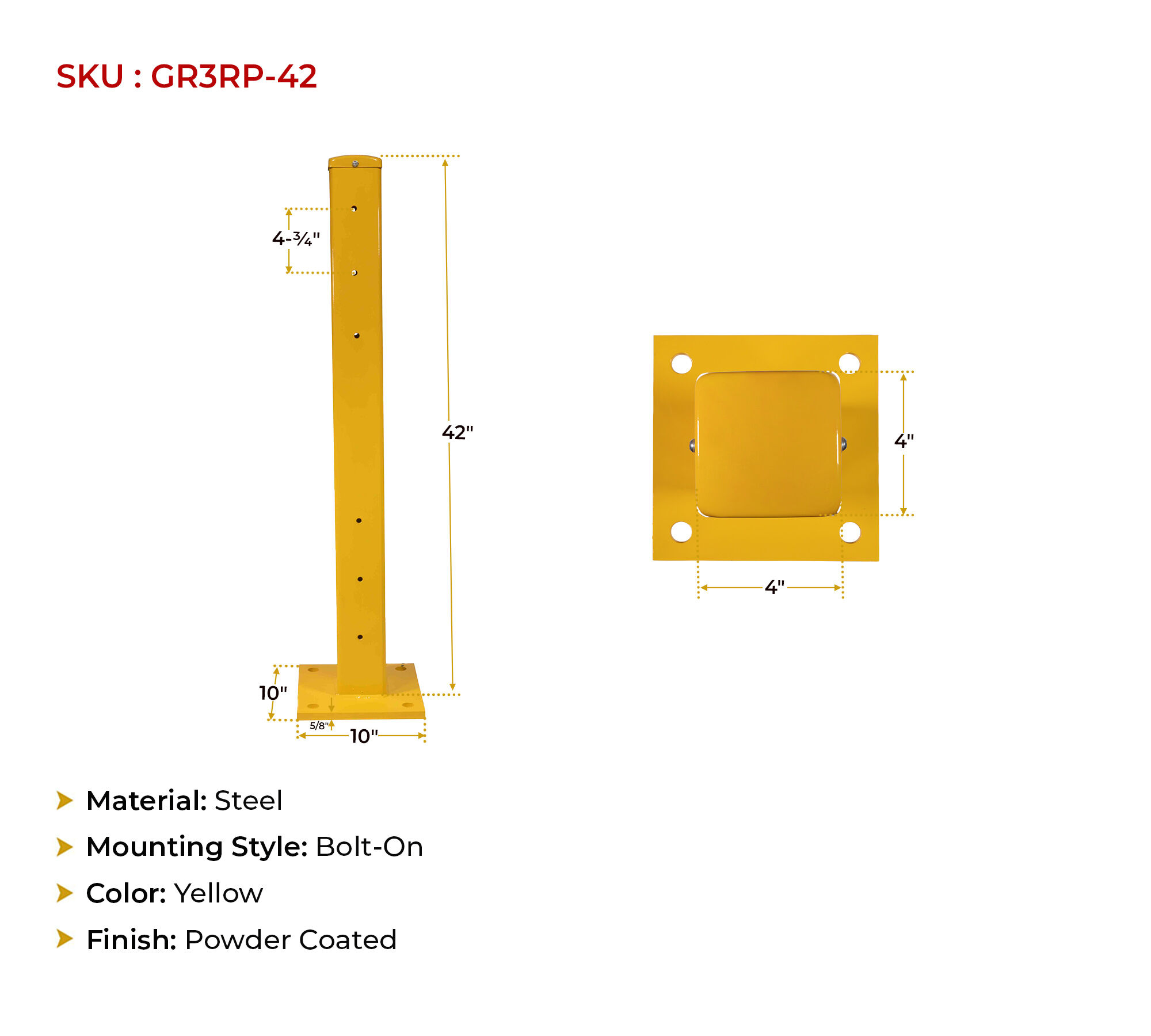

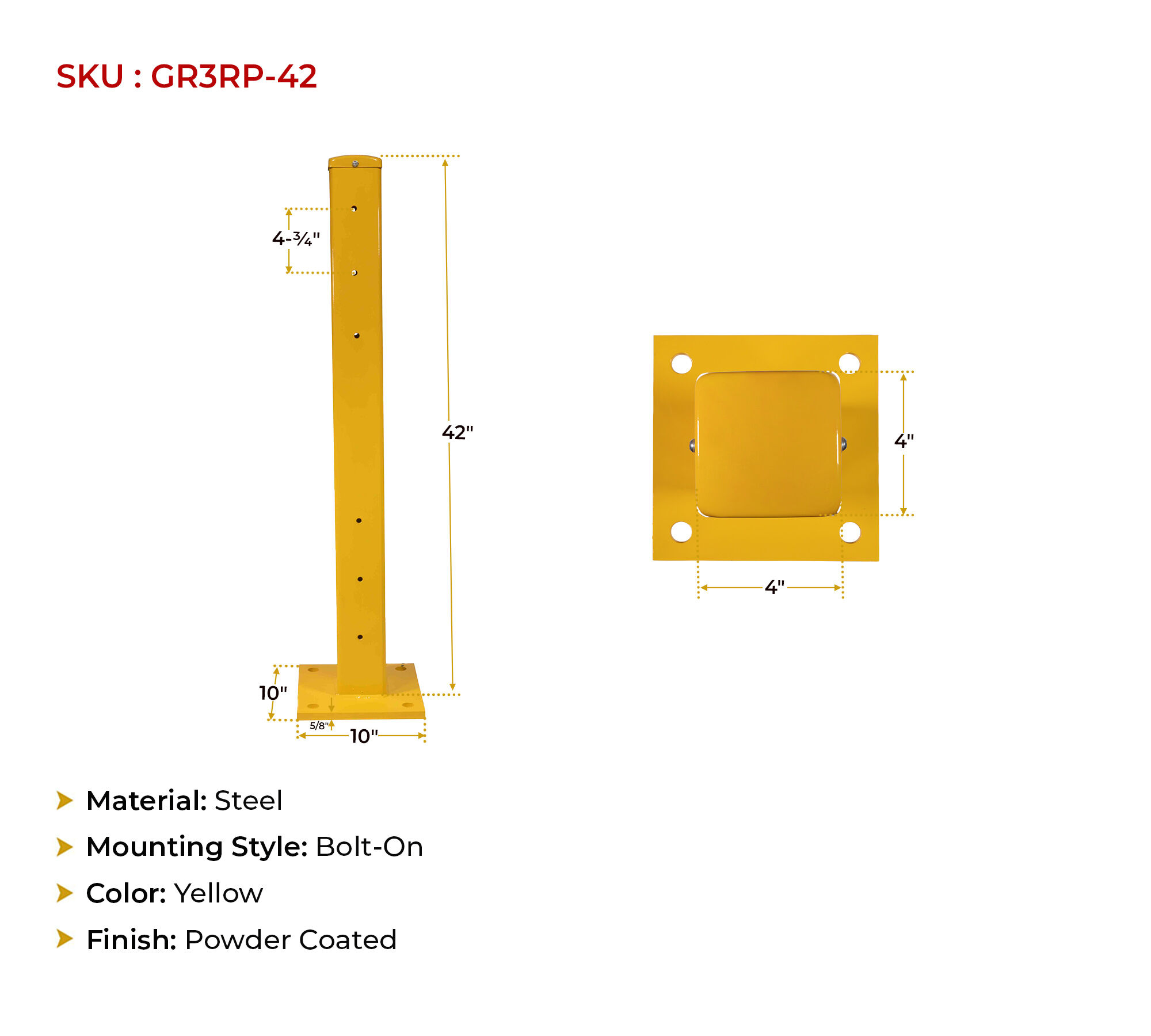

The Essential Guide to Bolt-On Steel Posts for Double 2-Rib Guard Rails, 42"H, Yellow

🏗️ Introduction to Guard Rail Posts

Guard rail posts are the backbone of industrial safety barrier systems. They anchor rails securely, providing a durable shield against collisions and workplace accidents. Built from heavy-duty steel and coated in high-visibility yellow, these posts serve as both a physical barrier and a visual warning for operators.

The Global Industrial™ Bolt-On Steel Post for Double 2-Rib Guard Rail, 42"H, Yellow is specifically designed for modular guard rail systems, making it easy to install, expand, or reconfigure safety zones. Its bolt-on design allows flexibility in fast-paced industrial environments where layouts frequently change. By combining strength, visibility, and compliance, these posts are essential for protecting people, equipment, and infrastructure in high-traffic workspaces.

🏢 Key Applications of Guard Rail Posts

- Warehouses & Distribution Centers

Guard rail posts help safeguard shelving, pallet racking, and storage systems from accidental forklift collisions. They also create clear pedestrian walkways, reducing the risk of worker injuries in busy traffic zones. By anchoring guard rails, they ensure a safer and more organized warehouse layout.

- Manufacturing Plants

In manufacturing facilities, guard rail posts separate production lines from vehicle paths, ensuring smooth and safe operations. This prevents forklifts from damaging expensive machinery or injuring workers. By reducing accidents, they also minimize costly downtime and equipment repairs.

- Loading Docks

Loading docks are high-risk areas where vehicles and workers often move in close quarters. Guard rail posts prevent trucks or forklifts from overshooting edges or hitting dock doors and walls. They create safer traffic flow while protecting both people and property.

- Parking Facilities & Garages

In crowded or multi-level parking structures, guard rail posts provide barriers that protect vehicles, walls, and structural elements from collisions. Their high visibility guides drivers, while also designating safe pedestrian zones to prevent accidents in tight spaces.

- Airports & Transportation Hubs

Airports and transit hubs experience constant movement of vehicles, carts, and passengers. Guard rail posts help channel traffic, protect equipment like baggage systems, and ensure passenger walkways remain secure. Their durability supports continuous use in demanding environments.

- Energy & Utility Facilities

At energy plants, substations, and utility areas, guard rail posts protect valuable assets such as transformers, tanks, and pipelines from accidental impacts. Their strong steel construction ensures long-term reliability in outdoor environments, enhancing both safety and compliance.

🔧 2. Major Safety Challenges Guard Rail Posts Solve

- Impact Resistance – Guard rail posts are built from heavy-duty steel, allowing them to absorb and deflect the force of forklifts, trucks, and carts. This prevents collisions from causing severe damage to workers, equipment, and building structures. By dispersing the impact, they extend the life of both safety systems and facility infrastructure.

- Clear Safety Boundaries – Posts create strong, visible barriers that separate pedestrians from moving vehicles and machinery. This clear division reduces confusion in busy environments and ensures that workers and operators can identify safe walkways and restricted areas at all times.

- Reduced Workplace Incidents – According to OSHA, vehicle collisions are one of the leading causes of warehouse and factory injuries. Guard rail posts directly address this by reducing accident frequency, protecting both employees and equipment while ensuring compliance with workplace safety standards.

- Visual Awareness – The posts are finished with a high-visibility yellow powder coat, which acts as a visual warning to drivers and workers alike. This helps prevent accidents in dimly lit warehouses or fast-paced environments, where quick recognition of safety barriers is critical.

- Durability Under Stress – Designed for repeated impacts, these posts maintain their structural integrity over years of use. Their rugged construction ensures long-term performance, making them a cost-effective investment that continues to provide reliable safety even under heavy-duty industrial conditions.

📌 3. Essential Features to Evaluate in Guard Rail Posts

- Material Construction – Guard rail posts are manufactured from heavy-gauge steel, giving them the strength to withstand repeated impacts from forklifts and other industrial vehicles. This robust construction ensures long-term resilience in tough environments such as warehouses, factories, and outdoor facilities, where safety demands are high.

- Height & Coverage – The standard 42-inch height is specifically chosen to provide full protection for pedestrians while meeting OSHA’s minimum requirements for safety barriers. This height ensures that guard rails are positioned at an effective level to block vehicles while still offering visibility and accessibility for workers.

- Finish & Protection – A bright powder-coated yellow finish not only provides maximum visibility but also resists rust, corrosion, and fading. This makes the posts suitable for both indoor and outdoor use, allowing them to perform reliably in harsh environments without losing their structural or visual effectiveness.

- System Compatibility – These posts are designed to work seamlessly with double 2-rib guard rail systems, delivering maximum strength and stability. Compatibility ensures that posts and rails fit together securely, eliminating weak points and creating a unified barrier that protects people, assets, and infrastructure.

- Installation Method – The bolt-on anchoring system simplifies the installation process, allowing posts to be securely fastened into concrete floors without welding. This design also makes it easy to relocate or expand safety barriers if facility layouts change, offering flexibility and long-term adaptability.

🏠 4. How to Select the Right Guard Rail Post

- For Warehouses – In warehouses where layouts often change, bolt-on posts are the best option. They provide modularity and flexibility, allowing managers to rearrange aisles, create new walkways, or expand storage zones without needing permanent construction. This adaptability saves both time and cost during reconfigurations.

- For Heavy-Duty Industrial Areas – Facilities with heavy forklift traffic or large machinery should use reinforced or double-rib guard rail systems. These posts are engineered to withstand repeated, high-impact collisions, ensuring long-term durability. Choosing reinforced systems reduces repair costs and guarantees ongoing protection for valuable equipment and workers.

- For Outdoor & Harsh Environments – Outdoor utility areas, loading docks, or chemical plants require posts with galvanized or weather-resistant coatings. These finishes protect against rust, moisture, and corrosion, ensuring the posts remain effective for many years even in challenging climates. This makes them a reliable choice for long-term safety.

- For Pedestrian Protection – When guard rail posts are used to protect workers, it’s essential to select posts with a standard 42-inch height, as this aligns with OSHA’s minimum barrier requirements. This ensures that rails are installed at an effective level to block vehicles while still allowing visibility and easy access for employees.

- For Budget-Sensitive Facilities – Businesses with limited budgets should consider modular post systems that can be expanded gradually. Instead of a one-time, large investment, companies can install posts in high-risk areas first and then scale up over time. This phased approach balances affordability with long-term workplace safety.

🛒 5. Recommended Products & Trusted Suppliers

| Model |

Description |

Height |

Supplier Link |

Best For |

| Global Industrial™ Bolt-On Steel Post, Double 2-Rib |

Heavy-duty steel, powder-coated, bolt-on installation |

42" |

Global Industrial |

Warehouses, factories |

| Global Industrial™ Modular Guard Rail System |

Posts + rails, flexible design |

18"–42" |

Global Industrial |

Facility-wide safety |

| Wildeck Guard Rail Posts |

Welded steel, OSHA-compliant |

42" |

Office-Supply-Hut |

Heavy-duty manufacturing |

| Impact Recovery Systems Flexible Post |

Flexible rebound post for lighter-duty traffic |

42" |

Grainger |

Outdoor traffic & loading zones |

🚨 6. Major Risks of Selecting the Wrong Guard Rail Post

- Incorrect Height – Choosing posts that are too short can leave employees, equipment, or infrastructure exposed to collisions. A post that doesn’t meet OSHA’s minimum 42-inch standard may allow vehicles to breach the barrier, undermining workplace safety. Ensuring the correct height is essential for effective protection.

- Weak or Thin Steel – Low-quality posts made from thinner steel or cheaper materials often bend, break, or collapse after only one impact. This compromises the safety of the entire barrier system and leads to expensive replacement costs. Investing in heavy-gauge steel posts ensures long-term durability and reliability.

- Incompatible Systems – Mismatching posts and rails creates weak points in the barrier, leaving dangerous gaps that vehicles can exploit. Incompatibility also makes maintenance and repairs more difficult, leading to safety concerns. Always ensure that posts are designed to work seamlessly with the selected guard rail system.

- Low Visibility – Posts with poor-quality coatings or faded paint lose their high-visibility advantage over time. This increases the likelihood of drivers missing safety barriers, especially in dim or high-traffic environments. A bright yellow powder-coated finish helps prevent collisions by keeping barriers clearly visible.

- Non-Compliance – Using posts that fail to meet OSHA or ANSI standards can result in failed inspections, costly fines, or liability issues in the event of an accident. Non-compliance not only endangers workers but also exposes businesses to legal and financial risks. Selecting certified, compliant posts ensures long-term protection and peace of mind.

📝 7. Compliance Regulations & Industry Standards

- OSHA Requirements – According to OSHA’s 1910.29 standard, guard rail systems must meet strict requirements for fall protection, minimum height, and barrier strength. Compliance ensures workers are shielded from vehicle accidents and falls, while also protecting businesses from fines, legal liability, and failed safety audits.

- ANSI Standards – The ANSI MH31.2 guidelines provide performance-based criteria for guard rail systems in industrial environments. These standards ensure barriers are tested against real-world impact forces, guaranteeing that posts and rails can withstand collisions without failing under stress.

- IBC (International Building Code) – The IBC often specifies where and how barriers must be installed, particularly in mixed-use or public-access facilities. It may dictate minimum placement distances, load-bearing strength, and material requirements to ensure that safety barriers meet universal building expectations.

- Local Codes & Fire Safety – Many municipalities introduce additional codes covering spacing, clearance, or fire safety concerns. For example, guard rail placement might be restricted near fire exits or utility access points. Verifying local regulations before installation avoids costly rework or failed inspections.

- Supplier Certifications – Before purchasing posts, always confirm that suppliers provide UL, ANSI, or OSHA compliance certifications. Verified documentation ensures the equipment has been independently tested and approved, giving businesses confidence in both safety and regulatory compliance.

🔍 8. Best Practices for Installing and Using Guard Rail Posts

- Anchor Properly – Guard rail posts should always be installed with heavy-duty anchor bolts secured into concrete floors. This ensures maximum stability and prevents posts from shifting during impact. Proper anchoring is the foundation of an effective barrier system and directly influences its ability to perform under stress.

- Conduct Routine Inspections – Even the strongest steel posts require periodic maintenance. Facilities should regularly check for loose bolts, rust, dents, or impact damage, repairing or replacing components promptly. Consistent inspections extend the lifespan of the system and help maintain compliance with OSHA standards.

- Match the Environment – Posts should be tailored to the setting in which they are used. For outdoor environments or corrosive areas, weatherproof or galvanized finishes are necessary to prevent rust. For indoor facilities, powder-coated posts provide durability and high visibility at a lower cost.

- Plan Traffic Flow – Strategic placement of posts is critical for safety. They should be installed in high-risk zones such as intersections, loading docks, or narrow aisles where collisions are most likely. Proper planning reduces bottlenecks, guides vehicles, and ensures maximum protection for both workers and assets.

- Expand with Growth – Facilities often expand or reorganize, and safety systems must keep pace. Modular guard rail posts allow businesses to extend protection gradually without replacing entire systems. This scalability makes them cost-effective while ensuring safety remains consistent as operations grow.

- Visibility Enhancements – In areas with low lighting or heavy traffic, posts should be reinforced with reflective tape, warning labels, or overhead signage. These enhancements improve driver awareness and reduce the chance of accidental collisions, especially during night shifts or in dim warehouses.

💰 9. Cost, ROI & Long-Term Value

- Initial Investment vs. Loss Prevention – While purchasing guard rail posts requires upfront costs, the expense is minimal compared to repairing damaged forklifts, racking systems, or structural walls after an accident. More importantly, preventing workplace injuries avoids costly medical claims, lawsuits, and compensation expenses, making posts a highly cost-effective safety investment.

- Insurance Benefits – Businesses that implement OSHA - compliant guard rail systems often benefit from lower insurance premiums. Demonstrating a proactive approach to workplace safety reassures insurers, reduces liability risks, and can create long-term savings that far exceed the initial installation costs.

- Longevity – High-quality steel guard rail posts are built to last for decades with minimal maintenance. Their powder-coated or galvanized finishes ensure resistance to rust, corrosion, and fading, making them a one-time investment that delivers reliable safety across years of demanding industrial use.

- Productivity Gains – By preventing accidents and protecting equipment, guard rail systems help reduce downtime, repairs, and workflow interruptions. A safer facility also boosts worker confidence and morale, leading to more efficient operations and consistent productivity.

- Scalable Safety – Bolt-on guard rail posts are modular and expandable, allowing facilities to start with high-risk zones and gradually extend protection as budgets allow. This scalability spreads costs over time, helping businesses balance affordability with comprehensive workplace safety.

🎯 10. Conclusion & Key Takeaways on Guard Rail Posts

- The Bolt-On Steel Post for Double 2-Rib Guard Rail, 42"H, Yellow stands out as a cornerstone of workplace safety. Its rugged steel construction, modular design, and OSHA-compliant visibility make it a dependable choice for safeguarding employees, equipment, and infrastructure in demanding environments.

- By selecting the right type of post for the application, businesses can address specific safety challenges such as forklift impacts, outdoor exposure, or high-traffic areas. Choosing compatible and compliant posts ensures long-term performance and prevents weak points in barrier systems.

- Regulatory compliance plays a critical role in maximizing both safety and financial protection. Following OSHA, ANSI, and local building codes not only keeps workers safe but also shields businesses from fines, liability claims, and insurance complications.

- Proper installation and routine maintenance significantly extend the lifespan of guard rail posts. Anchoring posts correctly, conducting inspections, and addressing wear promptly help maintain maximum protection, reducing the risk of accidents and costly downtime.

- In the long run, guard rail posts should be seen not just as barriers but as strategic safety investments. They minimize workplace accidents, protect valuable assets, improve operational efficiency, and deliver measurable returns by safeguarding operations for years to come.