🔥 Title: FIRE-RESISTANT VS FIRE-RETARDANT GLOVES: WHAT’S THE DIFFERENCE AND WHY IT MATTERS

🧤 DESCRIPTION:

Not all safety gloves are created equal. Learn the critical difference between fire-resistant and fire-retardant gloves, how each protects against heat and flames, and which is right for your industry—from welding and electrical work to manufacturing and construction. Discover key materials, performance ratings, and expert recommendations to help you choose the safest glove for the job.

Fire-resistant gloves, also known as fire-retardant, flame-resistant, or FR gloves, are designed to protect hands from burns, heat, and fire hazards. They are made from a variety of materials, including Kevlar, leather, Nomex, Aramid, and aluminized fabrics. These materials are chosen for their ability to withstand high temperatures, prevent ignition, and minimize heat transfer.

MATERIALS COMMONLY USED IN FIRE-RESISTANT GLOVES:

- Kevlar: A synthetic fiber known for its high strength and heat resistance, often used as a lining or in combination with other materials.

- Leather: Provides excellent abrasion resistance, puncture resistance, and can be treated for flame resistance.

- Nomex: A meta-aramid fiber that is flame-resistant and heat-resistant, commonly used in structural firefighting gear.

- Aramid fibers (like Kevlar and Nomex): Offer a good balance of heat resistance, strength, and durability.

- Aluminized fabrics: Reflect radiant heat and can be used as a layer in gloves to further enhance heat protection.

- Cotton and polyester blends: While not as inherently fire-resistant as other materials, they can be used as a comfortable inner lining.

- CarbonX: A non-flammable material that won't melt or shrink and is static-free.

KEY FEATURES AND PURPOSE:

Fire-resistant gloves are designed to:

- Resist Ignition: They are made from materials that naturally resist burning or are treated to prevent flames from easily igniting the glove.

- Withstand High Temperatures: They can endure significant heat without melting or dripping, which could cause further injury to the wearer.

- Minimize Heat Transfer: The materials used are chosen for their insulating properties, reducing the amount of heat that reaches the hand.

- Maintain Dexterity and Comfort: Despite their protective qualities, these gloves are designed to allow workers to perform tasks efficiently without restricting movement or causing discomfort.

- Provide Additional Protection: Depending on the specific application, they may also offer resistance to cuts, punctures, and abrasions

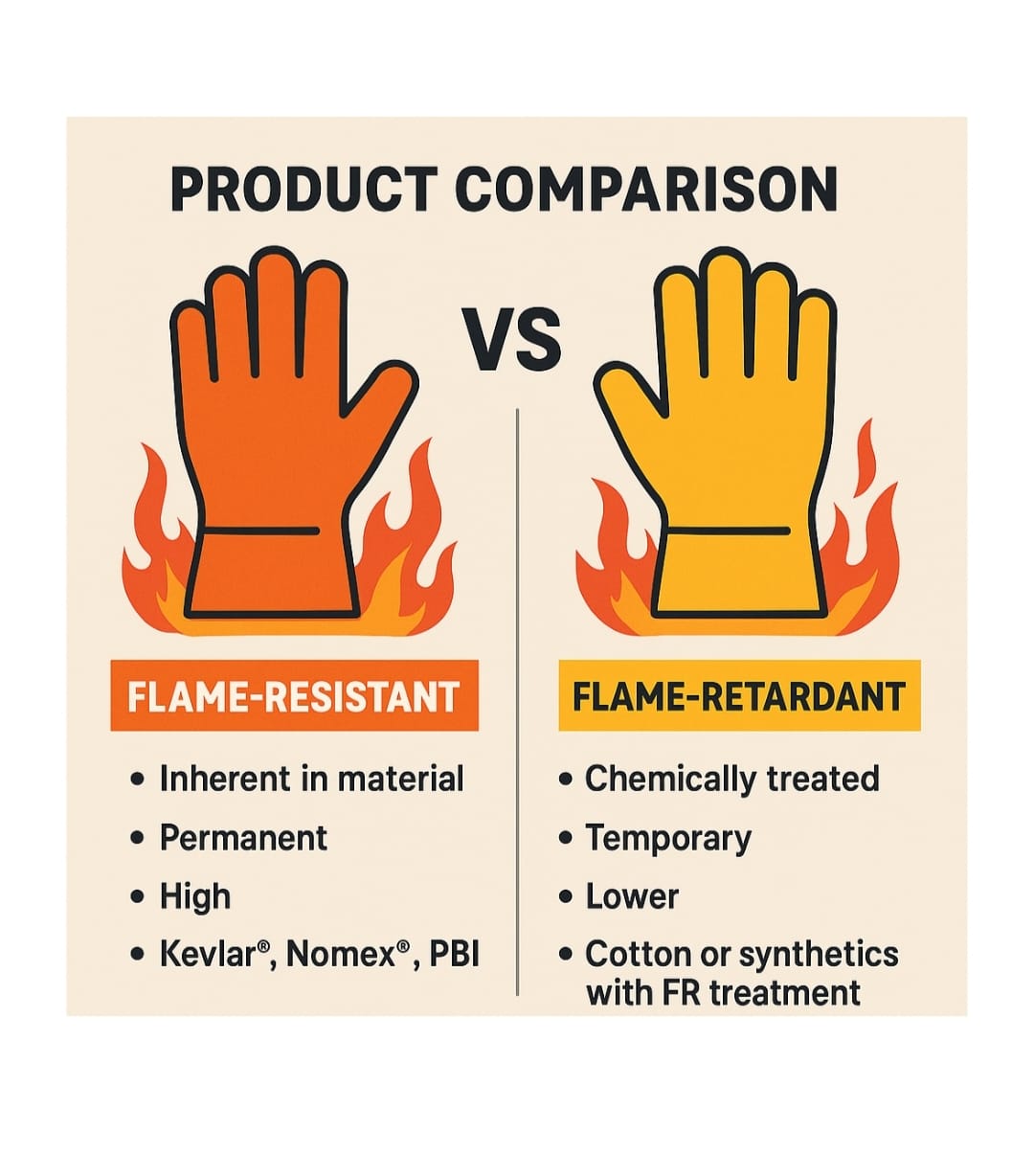

The terms "flame-resistant" and "flame-retardant" are often used interchangeably, but they refer to different properties when it comes to protective gloves (or other materials). Here's the key distinction:

🔥 FLAME-RESISTANT GLOVES

- Definition: Made from materials that are inherently resistant to catching fire.

- Material: The fibers themselves (e.g., Kevlar®, Nomex®, PBI) do not burn easily and will self-extinguish.

- Durability: The resistance is built into the fabric, so it lasts for the life of the glove, even after repeated washings or exposure to harsh conditions.

- Use Case: Ideal for environments with consistent or high-risk exposure to flames or arcs, such as firefighting, electrical work, welding, or petrochemical operations.

🔥 FLAME-RETARDANT GLOVES

- Definition: Made from materials that have been chemically treated to resist ignition.

- Material: Typically standard fabrics (like cotton or synthetic blends) treated with flame-retardant chemicals.

- Durability: The treatment can wear off over time, especially with washing or abrasion.

- Use Case: Suitable for short-term or lower-risk fire exposure where cost is a factor or full flame resistance is not necessary.

✅ SUMMARY COMPARISON

|

Feature

|

Flame-Resistant

|

Flame-Retardant

|

|

Fire resistance origin

|

Inherent in material

|

Chemically treated

|

|

Longevity of protection

|

Permanent

|

Temporary (can degrade over time)

|

|

Wash durability

|

High

|

Lower

|

|

Typical materials

|

Kevlar®, Nomex®, PBI

|

Cotton or synthetics with FR treatment

|

|

Ideal for

|

High-risk, long-term exposure

|

Lower-risk, short-term exposure

|

|

Cost

|

Higher

|

Lower

|

Numerous manufacturers and distributors specialize in providing flame-retardant gloves for B2B applications. Some of the most prominent names in this sector include:

- PIP (Protective Industrial Products): A global leader in hand protection and PPE, PIP Global Safety offers a wide variety of flame-resistant work gloves suitable for different requirements.

- MCR Safety: This manufacturer and distributor offers a broad range of PPE, including chemical and flame-resistant work gloves with various features like cut and impact protection.

- Honeywell International Inc.: A diversified technology and manufacturing company, Honeywell produces hardware and software solutions across various industries, including safety, with a focus on PPE like flame-resistant gloves.

- Youngstown Glove: Specializing in FR performance work gloves, Youngstown's flame-resistant gloves are tested to ASTM D6413 and EN 407 standards, ensuring they won't drip, melt, or ignite when exposed to flames and sparks.

- Mechanix Wear LLC: This manufacturer and supplier of high-performance glove wear offers heat-resistant gloves that meet standards for protection against arc flash, welding, and other hazards.

- Superior Glove Works Ltd.: With over a century of experience, Superior Glove is a prominent manufacturer of work gloves, including a range of flame-resistant options.

- Ansell Healthcare Products LLC: While more known for healthcare solutions, Ansell is a global leader in protective gloves and also offers industrial flame-resistant gloves.

- Wells Lamont Industrial, LLC: This manufacturer focuses on gloves and sleeve products, including those with cut and heat resistance for various industrial applications.

- Global Glove: This distributor and supplier offers a diverse selection of glove categories, including fire-resistant options.

- HexArmor: A manufacturer that offers a comprehensive line of safety gloves, including various models specifically designed for welding, arc flash protection, and high-heat applications.

Selecting flame-retardant gloves for your business? consider factors like:

- Specific Hazard: Determine the level of heat, flame, or arc flash protection required based on the work environment.

- Material: Choose gloves made from materials like Kevlar, CarbonX, or leather, each offering different levels of heat and cut resistance.

- Comfort and Dexterity: Ensure the gloves provide a comfortable fit and allow for necessary dexterity to perform tasks effectively.

- Compliance: Verify that the gloves meet relevant industry standards and regulations, such as NFPA or ASTM.

WHERE TO BUY FIRE RETARDANT GLOVES FOR BUSINESS

PIP (Protective Industrial Products): https://us.pipglobal.com Wikipedia+14Protective Industrial Products+14Protective Industrial Products+14

WHERE TO BUY FIRE RESISTANT GLOVES FOR BUSINESS

GOVERNMENT STANDARDS FOR FIRE RETARDANT GLOVES

1. OSHA regulations

- OSHA mandates employers to provide employees exposed to certain hazards, such as arc flashes, flames, or molten metal, with Flame-Resistant (FR) clothing, including gloves.

- FR clothing, by definition, must self-extinguish when the source of ignition is removed.

- OSHA's “269” standard (29 CFR 1910.269(l)(6)) specifically addresses flame-resistant clothing requirements for workers in the electric power industry, according to OSHA.

- It prohibits clothing that could melt onto the skin or ignite and continue to burn in the presence of an arc flash.

- Certain materials, including acetate, nylon, polyester, and rayon, are generally prohibited unless treated to withstand the conditions.

2. NFPA Standards

- For structural firefighting gloves, the relevant standard is NFPA 1971, which covers various aspects of firefighter protective ensembles.

- Gloves certified under NFPA 1971 must undergo testing by an independent third-party organization, notes Homeland Security.

- Key performance requirements include:

- Thermal Protective Performance (TPP): The glove body must have a TPP of at least 35.0, a second-degree burn time of at least 10 seconds, and a pain time of not less than 6 seconds, according to Homeland Security.

- Resistance to cuts, punctures, and heat.

- Dexterity and grip for manipulating tools and equipment.

- Resistance to penetration by liquids and chemicals, says Homeland Security.

- For wildland fire fighting, gloves must be certified compliant with NFPA 1977, according to US Forest Service documents.