Loading product details...

Loading product details...

Choosing the right packaging film is essential to ensure product safety, reduce damage, and optimize your warehouse and shipping operations. Two of the most commonly used solutions in the industrial packaging world are stretch wrap and shrink wrap. Though often confused, they serve very different purposes.

In this expert guide, we’ll compare stretch wrap vs. shrink wrap in detail, break down their differences, highlight key industry suppliers, and help you choose the best solution for your operation.

Stretch wrap film, shrink wrap packaging, pallet wrap, machine stretch film, hand stretch film, shrink film rolls, industrial packaging supplies, heat shrink wrap, palletizing wrap, stretch film manufacturers

Choosing the right stretch wrap film or shrink wrap packaging solution can significantly improve product protection, reduce damage, and enhance operational efficiency. This guide dives deep into the differences between hand stretch film, machine stretch wrap, and heat shrink film rolls, showcasing top suppliers and top-rated industrial packaging supplies.

Stretch wrap film, pallet wrapping film, hand stretch film, machine stretch wrap, shrink film packaging, heat shrink film rolls, industrial packaging supplies, tamper-evident shrink wrap, LLDPE stretch film, eco-friendly pallet wrap

When it comes to packaging and securing goods, stretch wrap and shrink wrap are two of the most widely used solutions in the industrial world. While they may look similar, their functions, materials, and applications are quite different. Understanding the distinction is essential for choosing the right solution for your operational needs, especially in logistics, manufacturing, retail, or eCommerce.

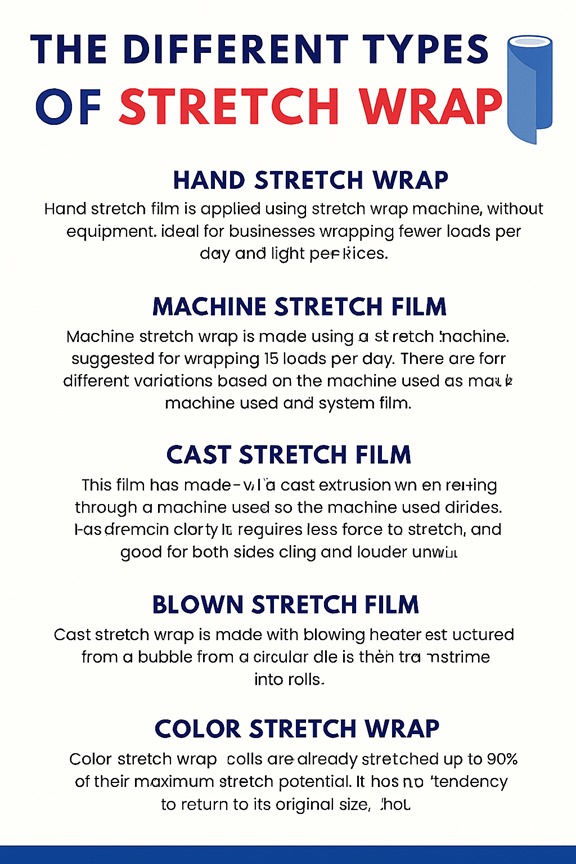

Stretch wrap—also called stretch film—is a highly stretchable plastic film typically made from linear low-density polyethylene (LLDPE). It is used to tightly wrap and secure products on pallets. The film clings to itself without the need for heat, making it ideal for bundling and stabilizing loads during transport or storage.

Shrink wrap, on the other hand, is a plastic film (typically polyolefin or PVC) that shrinks tightly around an item when heat is applied—usually via a heat gun or shrink tunnel.

|

Feature |

Stretch Wrap |

Shrink Wrap |

|

Application Method |

Manual or machine wrapping |

Requires heat (shrink tunnel/gun) |

|

Material Type |

LLDPE |

PVC, Polyolefin, PE |

|

Cling Mechanism |

Clings to itself |

Shrinks with heat to form a tight seal |

|

Best For |

Palletizing, bundling, load stability |

Retail, tamper-evident packaging |

|

Protects Against |

Dust, dirt, minor moisture |

Moisture, dust, tampering |

|

Common Industries |

Logistics, warehousing, manufacturing |

Retail, food, pharmaceuticals |

|

Energy Requirement |

None |

Requires heat |

|

Environmental Options |

Yes (pre-stretched, recyclable films) |

Yes (biodegradable & recyclable films) |

How to Choose the Right Packaging Film

|

Distributor |

Primary Focus |

Typical Use Case |

|

Global Industrial |

Industrial-grade cast stretch wrap |

Automation-friendly, ergonomic rolls ideal for high-output facilities |

|

Uline |

Two-sided cling, machine/hardware variety |

Versatile and reliable for both manual and machine . |

|

U.S. Packaging & Wrapping |

Discounted hand & machine stretch film |

Cost-effective options for small to medium operations |

|

Atlantic Packaging |

Equipment + film systems (e.g., Wulftec) |

Complete wrapping lines with engineering support |

|

Mr. Shrinkwrap |

Polyolefin shrink film & equipment |

Perfect for tamper-evident shrink wrap, retail multipacks, promotional goods |

✅ Final Recommendations